ANSSEN PRODUCTS

CCM & Spare parts

Copper mould is placed in the heart position of continuous casting machine(CCM), its function is to solidify the liquid steel pouring through the Submerged entry nozzle(SEN), guarantees required billet/bloom/slab with enough thick shell to be obtained.

ANSSEN Copper Plate manufacturing company is equipped with internationally advanced CNC machine and electroplating equipments, max.width 3800mm,ensure each client’s needs will be met.

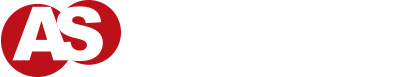

The mould assembly is the key part of the continuous casting machine,and its structural performance directly affects the production and quality of the continuous casting billet.

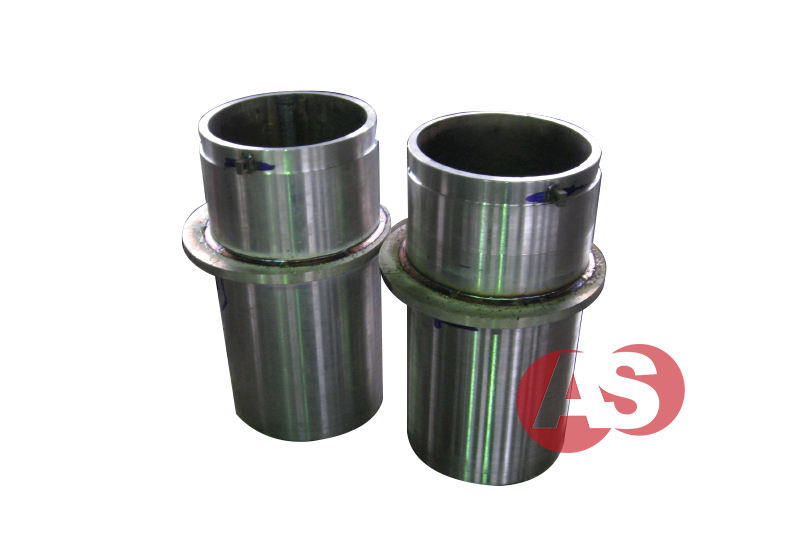

Made from high quality stainless steel, by extrusion & pressing method, ANSSEN water jacket ensures even cooling which greatly eliminates billet cracks and rhombic.

Greatly improving the operation condition of CCM shop by decreasing heat radiation.

Brass Water Jet Flat Fan Spray Nozzles;Full cone brass and stainless CCM spray nozzles

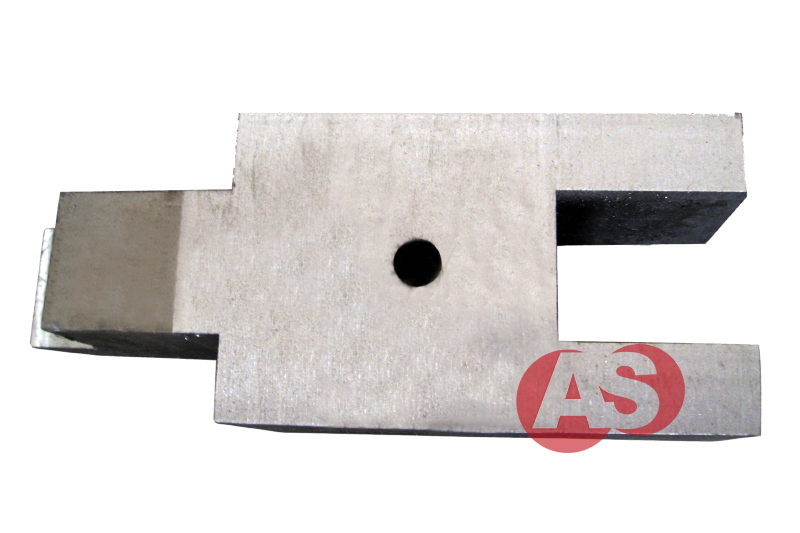

The dummy bar is used to tract and lead the cooled and solidified strand and pull it out by the withdrawal and straightening machine.

The essence of electromagnetic stirring is to agitate molten steel in casting blank, therefore to change and optimize the transfer of molten steel and heat exchange in the casting blank, and finally achieve targets of quality improvement and higher productivity.